One of the most important cultural practices here at Stow Acres Country Club is spraying our greens, tees and fairways. On average, we spray twice each week. We have two dedicated sprayers, one 175 gallon Spraytek DS175 for greens and tees, and a 300 gallon Toro Multipro 5700 for fairways. Given the volume of the tanks, and the precision with which the sprays are mixed, it can take upwards of an hour to fully load the sprayer. Each spray is typically 2-3 loads, which requires 2-3 hours or more of mixing and loading the spray. This season, we decided to change the process up a little.

We built a Pre-Mix Tank to facilitate mixing the spray while the spray technician is in the field treating the turf. The first step in the process was selecting a tank. We used a 275 gallon bulk fertilizer tank. 275 gallons of water, at 8.35 lbs per gallon, weighs 2300 lbs. With this in mind, we built a pressure treated stand of the same design as a hot tub deck. The stand also includes an area to stand on while loading the mix.

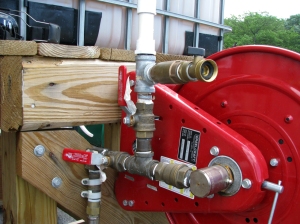

The tank was then modified to fit our design. We cut in a bulkhead with straining screen. The mix tank is powered by a 3/4 hp sump pump that drives a sprayer fill valve, in line strainer screen with bypass, and agitation nozzles to keep the products adequately mixed prior to loading. The tank is filled from our 120 psi South Course irrigation. An inline strainer screen filters the water before entering the tank. A custom aluminum fill hose frame was built and hinged to the tank. To facilitate the arm swinging without binding the fill hoses, we installed swing joints at both pivot points (upper and lower fill hoses). A platform was mounted to the tank cage with a cutout for the calibrated mixing cup.

Once we started using the mix tank, the time spent by the spray technician at the shop between loads has decreased from an hour or more, to only 5 minutes.

After using the mix tank for a couple weeks, we added a few new features to make it more usable. To facilitate faster filling, we plumbed the irrigation water from the South Course directly into the tank. Filling the entire 275 gallon tank with the irrigation line takes under 5 minutes. To help screen out any of the debris that makes it through the irrigation lines, we installed a fine mesh strainer screen. There’s also a quick disconnect in line, in case we ever have to move the tank for some reason. In the event that the irrigation is not pressurized, a 3/4″ female hose thread swivel connector was installed to allow the hose from the well water to be hooked up to the fill line.

For ease of rinsing containers and the mix tank itself, we also installed a 6′ hose with quick connect and a nozzle to the fill line. Valves allow one or both to be operated at the same time.

For more information on the mix tank, feel free to comment on this post, or contact me at JParker@StowAcres.com.

________________

Justin Parker

Equipment Manager

Stow Acres Country Club

http://golfcoursetech.wordpress.com/

Justin is a devoted Christian, husband, father to two daughters, golf course mechanic, entrepreneur and web enthusiast.

Justin attended UMass Amherst, where he studied Mechanical Engineering, Computer Science, Mathematics, and 3D Modelling and Animation and has completed the Turfgrass Management Certificate Program at Ohio State University. Justin works at Stow Acres Country Club in Stow, Massachusetts. Stow Acres is a 36 hole, semi-private, family owned facility.

In addition to working at Stow Acres, Justin owns Synergy Offroad, a 4×4 enthusiast ecommerce site.

We built a Pre-Mix Tank to facilitate mixing the spray while the spray technician is in the field treating the turf. The first step in the process was selecting a tank. We used a 275 gallon bulk fertilizer tank. 275 gallons of water, at 8.35 lbs per gallon, weighs 2300 lbs. With this in mind, we built a pressure treated stand of the same design as a hot tub deck. The stand also includes an area to stand on while loading the mix.

The tank was then modified to fit our design. We cut in a bulkhead with straining screen. The mix tank is powered by a 3/4 hp sump pump that drives a sprayer fill valve, in line strainer screen with bypass, and agitation nozzles to keep the products adequately mixed prior to loading. The tank is filled from our 120 psi South Course irrigation. An inline strainer screen filters the water before entering the tank. A custom aluminum fill hose frame was built and hinged to the tank. To facilitate the arm swinging without binding the fill hoses, we installed swing joints at both pivot points (upper and lower fill hoses). A platform was mounted to the tank cage with a cutout for the calibrated mixing cup.

Once we started using the mix tank, the time spent by the spray technician at the shop between loads has decreased from an hour or more, to only 5 minutes.

After using the mix tank for a couple weeks, we added a few new features to make it more usable. To facilitate faster filling, we plumbed the irrigation water from the South Course directly into the tank. Filling the entire 275 gallon tank with the irrigation line takes under 5 minutes. To help screen out any of the debris that makes it through the irrigation lines, we installed a fine mesh strainer screen. There’s also a quick disconnect in line, in case we ever have to move the tank for some reason. In the event that the irrigation is not pressurized, a 3/4″ female hose thread swivel connector was installed to allow the hose from the well water to be hooked up to the fill line.

For ease of rinsing containers and the mix tank itself, we also installed a 6′ hose with quick connect and a nozzle to the fill line. Valves allow one or both to be operated at the same time.

For more information on the mix tank, feel free to comment on this post, or contact me at JParker@StowAcres.com.

________________

Justin Parker

Equipment Manager

Stow Acres Country Club

http://golfcoursetech.wordpress.com/

Justin is a devoted Christian, husband, father to two daughters, golf course mechanic, entrepreneur and web enthusiast.

Justin attended UMass Amherst, where he studied Mechanical Engineering, Computer Science, Mathematics, and 3D Modelling and Animation and has completed the Turfgrass Management Certificate Program at Ohio State University. Justin works at Stow Acres Country Club in Stow, Massachusetts. Stow Acres is a 36 hole, semi-private, family owned facility.

In addition to working at Stow Acres, Justin owns Synergy Offroad, a 4×4 enthusiast ecommerce site.

4 Comments

impressive. How much did you end up spending?

The major parts of the mix tank are:

Bulk fertilizer tank: $0 (we had one laying around... I’m sure your

chemical supplier could get you one if you don’t have an extra)

Ridgid 1 hp cast iron sump pump: $250-300. We bought one with a

water level switch, which we removed. The operator just needs to monitor when

the sump pump starts taking in air and then he shuts it off. The switch was

causing the pump to shut off with approx 40 gallons left in the tank.

Bulkhead fittings for plumbing: $25-30 http://www.tank-depot.com/product.aspx?id=1018

16” hinged manway: $50 http://www.tank-depot.com/product.aspx?id=1035

16” strainer basket: $45 http://www.tank-depot.com/productdetails.aspx?part=16SCREEN

(2) strainer setups out of the Cushman Spraytek DS175 parts manual

(2 each of parts 57-115, 57-116, 57-118, and 57-117s): $100

(6) agitator nozzle setups out of the Cushman Spraytek DS175 parts

manual (2 each of parts 16-050 and 64-581): $50

Watertight switch setup for sump pump and associated wiring:

$15

1.5” hose for filling sprayer, approximately 15 feet:

$75

Aluminum for swingarm: $40

Hanger brackets for mounting fill hose to swing arm: $10

PVC, valves, and fittings for plumbing: $50

(2) Swing joints: $60

----------------------------------------------------

Parts Total: $800

The PT wood for the stand was probably another $250.

Time spent on the project: approx 25 man hours.

All in all, it probably cost us around $1500 between labor and materials.

I can say that it’s definitely getting used though.

Let me know if you have any questions at all, I’m glad to help.

Where did you get that tank from?

Storage Tanks Manufacturers2022

Underground Septic Tank2022

Water Storage Tanks2022

Storage Tannks Manufacturers2022

Diesel Storage Tank2022

Oil Storage Tank2022

Silos Storage Tank2022

Ss Storage Silos2022

Fly Ash Silos2022

EmoticonEmoticon